This week at RS Motor engine maintenance service, a new reconditioning job of cogeneration engine components has been carried out. This time, it’s the intercooler of a Jenbacher engine. These maintenance processes are performed by inspecting all intercooler components and replacing the necessary ones with genuine and/or original OEM spare parts for Jenbacher engines, Deutz...

HomeTag

engine overhaul - Rsmotorps

Reconditioning of cylinder heads for Caterpillar 170 engines, repair of Deutz-Mwm engine overhaul, Jenbacher and Guascor engines

March 13, 2024by Analía

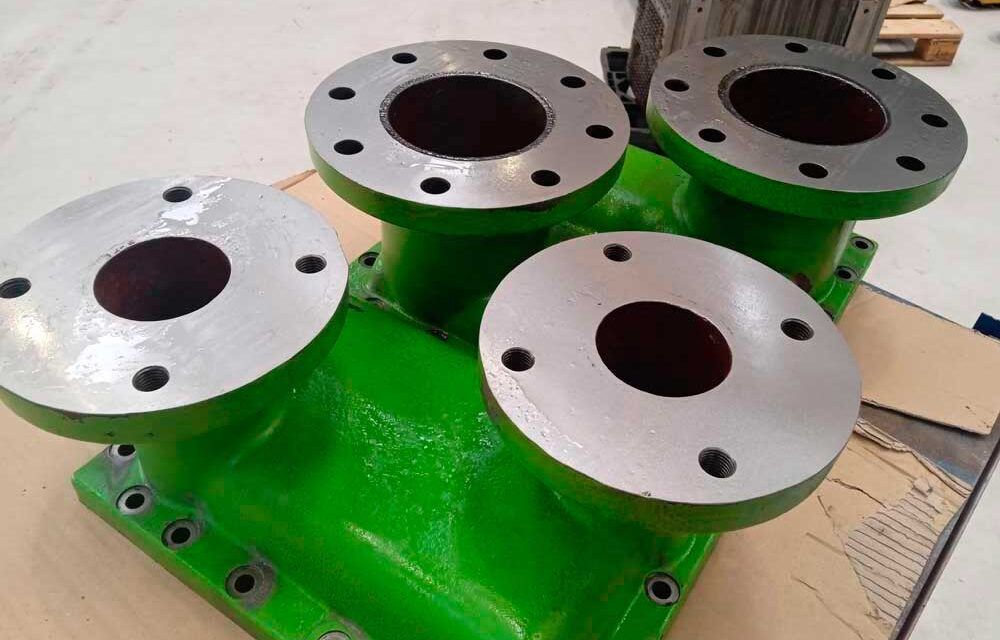

At RS Motor, we take pride in sharing one of the latest projects from our engine repair workshop. This week, we have completed a new reconditioning project for Deutz-Mwm engine overhaul, Jenbacher, and Guascor cogeneration engine cylinder heads. Specifically, we have worked on Caterpillar engine cylinder heads, more specifically the CAT CG 170 engine model,...

Engine maintenance service of Guascor FGLD 240

February 23, 2024by Analía

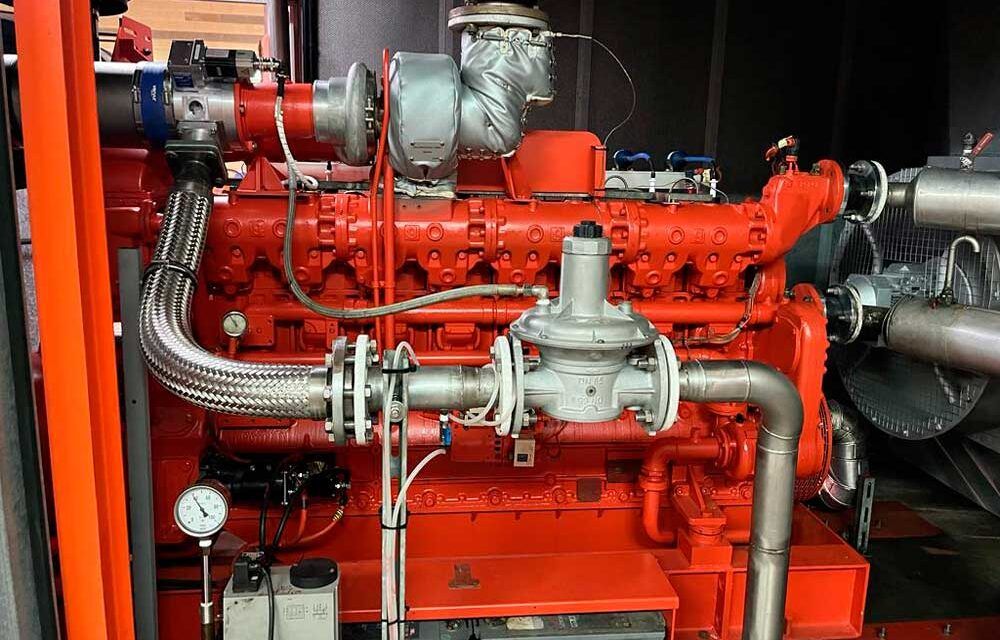

Recently, RS Motor has completed the R3 engine maintenance service on a Guascor FGLD 240 engine. The R3 maintenance is the most comprehensive one performed on Guascor engines and is also known as an overhaul. In this case, the engine was sent to RS Motor’s facilities where the maintenance tasks were carried out. RS Motor...

At RS Motor engine maintenance service, one of the most common tasks we carry out is the repair and maintenance of water pumps. These interventions are performed as part of scheduled maintenance for cogeneration and marine engine overhaul, as well as in response to situations where water leaks or other issues such as low pressure...

Jenbacher gas engine overhaul J620

December 7, 2023by Analía

This week, RS Motor’s workshop has successfully completed another Jenbacher gas engine overhaul and maintenance process, focusing on cogeneration engines. On this occasion, a Jeneplacing the necessary wear elements, reassembling them with new gaskets and carrying out the relevant dimensional analyses and tests in each case. It should be noted that all the spare parts...

Overhaul of Jenbacher engines, Deutz Mwm and Guascor engines

September 19, 2023by Analía

Previously we were talking about the small maintenance steps, today it’s time to talk about the extended scope maintenance carried out at the client’s facilities, such as the overhaul of Jenbacher engines, Guascor, and Deutz engines. At RS Motor, we specialize in cogeneration engine maintenance and perform all maintenance steps, from minor to complete overhauls....

RS Motor specialises in carrying out all the work involved in the repair and/or cogeneration engine maintenance service in industrial plants. By definition, preventive maintenance is a type of intervention linked to the number of hours that the engine is running. This interval of hours is always set by the engine manufacturer, which is why...

In addition to engine maintenance service, Rs Motor focuses a large part of its activity on the reconditioning of parts and equipment subject to wear in cogeneration engines. Below, we show you a brief summary of the most important repair works of parts that we usually carry out in our workshop: Cylinder head reconditioning: Replacement...

Overhaul of Jenbacher engines

June 26, 2023by Analía

One of the main activities carried out by Rs Motor is the performance of preventive maintenance steps included in the scope of the Manufacturer’s Maintenance Plans. Overhaul of Jenbacher engines, Deutz-Mwm, Caterpillar, Guascor, Rolls-Royce, Scania or Iveco, are some examples of industrial engine manufacturers on which Rs Motor carries out this type of action. The...

Do you need a gas engine for your power plant?. If yes, RS Motor is your best choice. With more than 10 years of experience in the cogeneration market, at RS Motor you can find gas engines in stock. Nowadays, in our warehouse we have various different gas engines such as MWM TCG2020V12, MWM TCG2020V16,...